PC 3002 VARIO selectVARIO® chemistry pumping unit

Overview

- VACUU·SELECT vacuum controller with graphical user interface and predefined applications simplifies work in the laboratory

- automatic boiling point detection and adjustment of the vacuum for short process times

- compact and efficient, good ultimate vacuum even with open gas ballast valve

- very quiet, low-vibration operation and extra long service intervals

- excellent environmental compatibility through low energy consumption and efficient solvent recovery

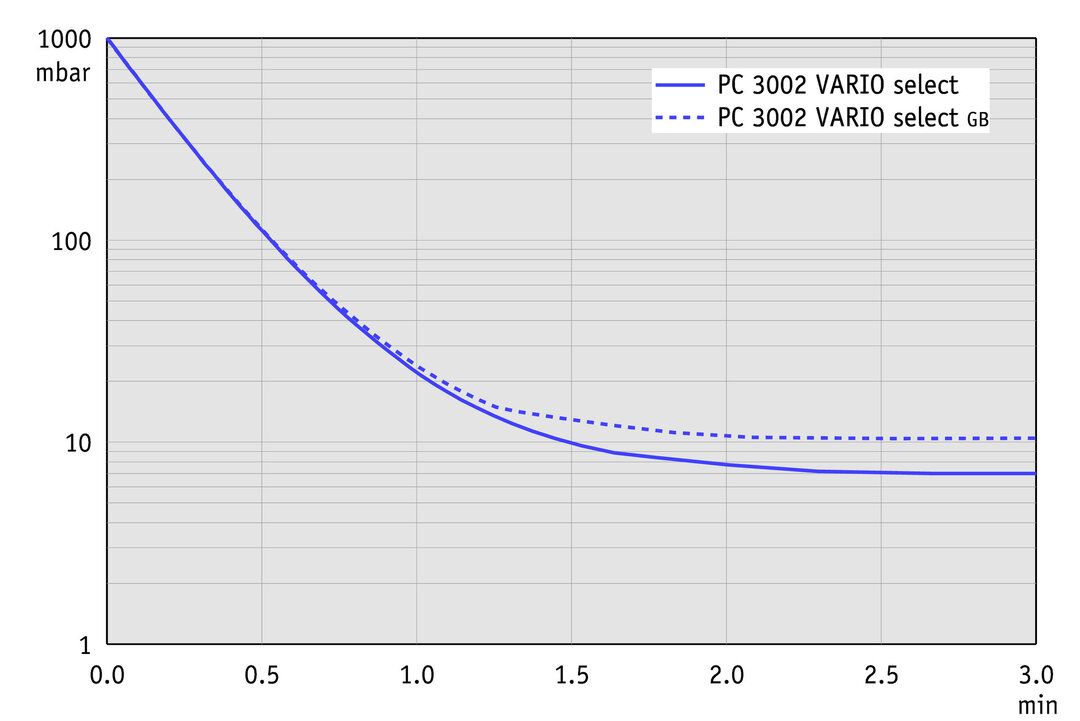

Ultimate vacuum

7 mbar

Ultimate vacuum with gas ballast

12 mbar

Max. pumping speed 50 Hz

2.8 m3/h

VARIO® chemistry pumping unit in action

The PC 3002 VARIO select pumping unit precisely controls the vacuum level in order to achieve unparalleled process control. This two stage MZ 2C VARIO pump at the core of the PC 3002 VARIO is suitable for work with most common solvents. The integrated VACUU·SELECT controller provides an easy-to-use, application based interface that covers all common lab applications. The VACUU·SELECT controller has you covered. Use manual set-point-control for simple processes, run fully automated distillations, or create your own application with simple drag-and-drop editing. For solvent evaporation, the VACUU·SELECT controller detects the boiling point and automatically adjusts the vacuum process as necessary. The application, desired vacuum, and other parameters can also be combined or controlled individually. The pump runs only as fast as necessary due to the VARIO control. This extends the maintenance intervals and makes the pumping unit whisper-quiet. The inlet separator, made of glass with protective coating, prevents particles and liquid droplets from entering the pump. The exhaust vapor condenser provides nearly 100% recovery of solvents for economical recycling and environmental protection.

für Zoom klicken

für Zoom klicken

Technical data and graphs

| Max. pumping speed 50 Hz | 2.8 m3/h | |

| Max. pumping speed 60 Hz | 1.65 cfm | |

| Ultimate vacuum | 7 mbar / 5 torr | |

| Ultimate vacuum with gas ballast | 12 mbar / 9 torr | |

| Number of heads | 2 | |

| Number of stages | 2 | |

| Vacuum controller | VACUU·SELECT | |

| Lower ambient temperature (operation) | 10 °C | |

| Upper ambient temperature (operation) | 40 °C | |

| Lower ambient temperature (storage) | -10 °C | |

| Upper ambient temperature (storage) | 60 °C | |

| Max. back pressure (abs.) | 1.1 bar | |

| Inlet connection | Hose nozzle DN 8-10 mm | |

| Outlet connection | Hose nozzle DN 8-10 mm | |

| Coolant connection | 2 x hose nozzle DN 6-8 mm | |

| Rated motor power | 0.53 kW | |

| Protection class IEC 60529 | IP 20 | |

| Dimension L in mm | 419 mm | |

| Dimension B in mm | 243 mm | |

| Dimension H in mm | 457 mm | |

| Weight | 17.9 kg | |

| Noise (sound pressure level) in dBA at 50 Hz or 1500 rpm/62% (VARIO)/1500 rpm (VARIO-SP)/12500 Upm (VACUU·PURE®) | 43 dBA | |

| ATEX conformity | II 3/- G Ex h IIC T3 Gc X Internal Atm. only | |

| NRTL certification | No | |

| Items supplied | Pumping unit completely mounted, ready for use, with manual. | |

| Rated mains voltage range 1 | 200-230 V | |

| Mains frequency 1 | 50-60 Hz | |

| Interface | Ethernet (RJ45): Modbus TCP / USB (Type A): Data transfer, software update, RS-232 (additional adapter required) |

Downloads

Equipment

VARIO® chemistry pumping unit in action

The PC 3002 VARIO select pumping unit precisely controls the vacuum level in order to achieve unparalleled process control. This two stage MZ 2C VARIO pump at the core of the PC 3002 VARIO is suitable for work with most common solvents. The integrated VACUU·SELECT controller provides an easy-to-use, application based interface that covers all common lab applications. The VACUU·SELECT controller has you covered. Use manual set-point-control for simple processes, run fully automated distillations, or create your own application with simple drag-and-drop editing. For solvent evaporation, the VACUU·SELECT controller detects the boiling point and automatically adjusts the vacuum process as necessary. The application, desired vacuum, and other parameters can also be combined or controlled individually. The pump runs only as fast as necessary due to the VARIO control. This extends the maintenance intervals and makes the pumping unit whisper-quiet. The inlet separator, made of glass with protective coating, prevents particles and liquid droplets from entering the pump. The exhaust vapor condenser provides nearly 100% recovery of solvents for economical recycling and environmental protection.

für Zoom klicken

für Zoom klicken

Technical data and graphs

| Max. pumping speed 50 Hz | 2.8 m3/h | |

| Max. pumping speed 60 Hz | 1.65 cfm | |

| Ultimate vacuum | 7 mbar / 5 torr | |

| Ultimate vacuum with gas ballast | 12 mbar / 9 torr | |

| Number of heads | 2 | |

| Number of stages | 2 | |

| Vacuum controller | VACUU·SELECT | |

| Lower ambient temperature (operation) | 10 °C | |

| Upper ambient temperature (operation) | 40 °C | |

| Lower ambient temperature (storage) | -10 °C | |

| Upper ambient temperature (storage) | 60 °C | |

| Max. back pressure (abs.) | 1.1 bar | |

| Inlet connection | Hose nozzle DN 8-10 mm | |

| Outlet connection | Hose nozzle DN 8-10 mm | |

| Coolant connection | 2 x hose nozzle DN 6-8 mm | |

| Rated motor power | 0.53 kW | |

| Protection class IEC 60529 | IP 20 | |

| Dimension L in mm | 419 mm | |

| Dimension B in mm | 243 mm | |

| Dimension H in mm | 457 mm | |

| Weight | 17.9 kg | |

| Noise (sound pressure level) in dBA at 50 Hz or 1500 rpm/62% (VARIO)/1500 rpm (VARIO-SP)/12500 Upm (VACUU·PURE®) | 43 dBA | |

| ATEX conformity | II 3/- G Ex h IIC T3 Gc X Internal Atm. only | |

| NRTL certification | No | |

| Items supplied | Pumping unit completely mounted, ready for use, with manual. | |

| Rated mains voltage range 1 | 200-230 V | |

| Mains frequency 1 | 50-60 Hz | |

| Interface | Ethernet (RJ45): Modbus TCP / USB (Type A): Data transfer, software update, RS-232 (additional adapter required) |

für Zoom klicken

für Zoom klicken