PC 3001 VARIOproVARIO® chemistry pumping unit

Overview

- easily operated CVC 3000 vacuum controller with clear text menus and integrated venting valve

- automatic optimization of the vacuum level throughout the process for high process reproducibility and unattended operation, short process times due to zero-fluctuation (hysteresis-free) vacuum control - even for large amounts of vapor

- compact and powerful; excellent ultimate vacuum, even with continuous condensate purge

- whisper quiet and ultra low vibration

- excellent environmental friendliness due to low power consumption and efficient solvent recovery

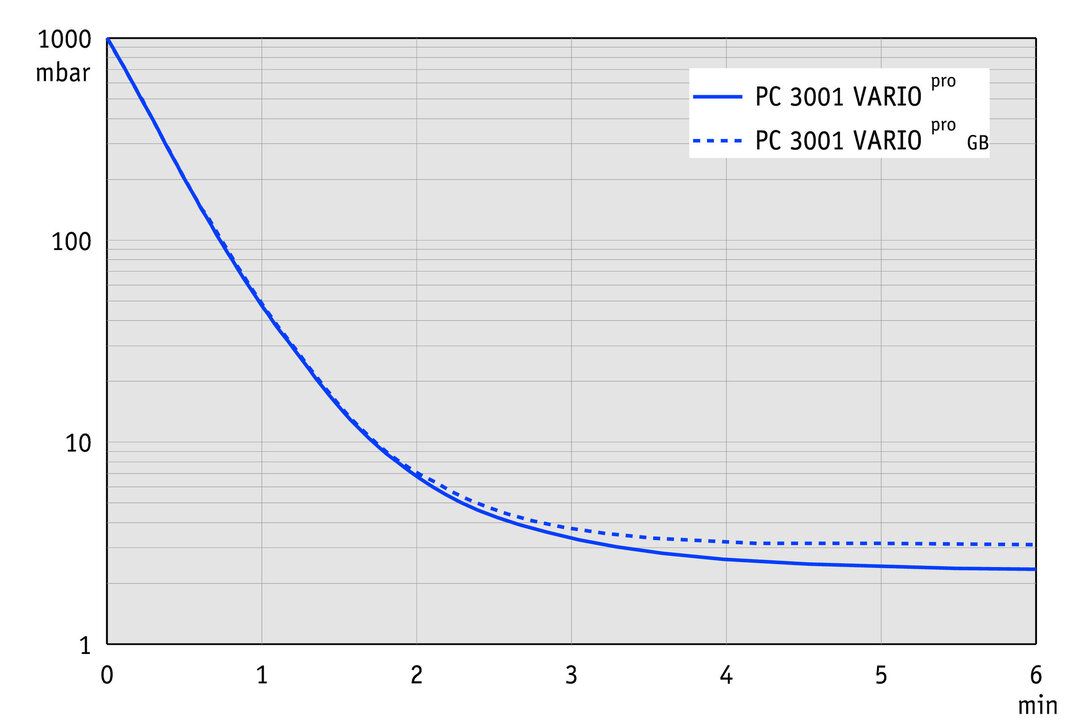

Ultimate vacuum

2 mbar

Ultimate vacuum with gas ballast

4 mbar

Max. pumping speed 50 Hz

2 m3/h

VARIO® chemistry pumping unit in action

This VARIO® chemistry pumping unit optimizes vacuum conditions automatically by precisely and continuously adjusting the diaphragm pump´s motor speed. Thanks to the motor speed control the pump operates only when vacuum is needed, saving energy and reducing maintenance. The integrated vacuum controller enables fully automatic evaporation at a push of a button. Low space requirements, light weight and low operational noise contribute further to this unit’s flexibility and popularity for laboratory use. The PC 3001 VARIOpro is ideal for vacuum applications with high boiling point solvents. The inlet separator, made of glass with a protective coating, prevents droplets and particles from entering the pump. The highly efficient insulated exhaust vapor condenser has a very compact design and provides near-100-percent recovery of solvents.

für Zoom klicken

für Zoom klicken

Technical data and graphs

| Max. pumping speed 50 Hz | 2 m3/h | |

| Max. pumping speed 60 Hz | 1.18 cfm | |

| Ultimate vacuum | 2 mbar / 1.5 torr | |

| Ultimate vacuum with gas ballast | 4 mbar / 3 torr | |

| Number of heads | 4 | |

| Number of stages | 3 | |

| Vacuum controller | CVC 3000 | |

| Lower ambient temperature (operation) | 10 °C | |

| Upper ambient temperature (operation) | 40 °C | |

| Lower ambient temperature (storage) | -10 °C | |

| Upper ambient temperature (storage) | 60 °C | |

| Max. back pressure (abs.) | 1.1 bar | |

| Inlet connection | Hose nozzle DN 6-10 mm | |

| Outlet connection | Hose nozzle DN 8-10 mm | |

| Coolant connection | 2 x hose nozzle DN 6-8 mm | |

| Rated motor power | 0.16 kW | |

| Protection class IEC 60529 | IP 20 | |

| Dimension L in mm | 300 mm | |

| Dimension B in mm | 306 mm | |

| Dimension H in mm | 400 mm | |

| Weight | 7.7 kg | |

| Noise (sound pressure level) in dBA at 50 Hz or 1500 rpm/62% (VARIO)/1500 rpm (VARIO-SP)/12500 Upm (VACUU·PURE®) | 42 dBA | |

| ATEX conformity | II 3/- G Ex h IIC T3 Gc X Internal Atm. only | |

| NRTL certification | Yes | |

| Items supplied | Pumping unit completely mounted, ready for use, with manual. | |

| Rated mains voltage range 1 | 200-230 V | |

| Rated mains voltage range 2 | 100-120 V | |

| Mains frequency 1 | 50-60 Hz | |

| Mains frequency 2 | 50-60 Hz |

Equipment

VARIO® chemistry pumping unit in action

This VARIO® chemistry pumping unit optimizes vacuum conditions automatically by precisely and continuously adjusting the diaphragm pump´s motor speed. Thanks to the motor speed control the pump operates only when vacuum is needed, saving energy and reducing maintenance. The integrated vacuum controller enables fully automatic evaporation at a push of a button. Low space requirements, light weight and low operational noise contribute further to this unit’s flexibility and popularity for laboratory use. The PC 3001 VARIOpro is ideal for vacuum applications with high boiling point solvents. The inlet separator, made of glass with a protective coating, prevents droplets and particles from entering the pump. The highly efficient insulated exhaust vapor condenser has a very compact design and provides near-100-percent recovery of solvents.

für Zoom klicken

für Zoom klicken

Technical data and graphs

| Max. pumping speed 50 Hz | 2 m3/h | |

| Max. pumping speed 60 Hz | 1.18 cfm | |

| Ultimate vacuum | 2 mbar / 1.5 torr | |

| Ultimate vacuum with gas ballast | 4 mbar / 3 torr | |

| Number of heads | 4 | |

| Number of stages | 3 | |

| Vacuum controller | CVC 3000 | |

| Lower ambient temperature (operation) | 10 °C | |

| Upper ambient temperature (operation) | 40 °C | |

| Lower ambient temperature (storage) | -10 °C | |

| Upper ambient temperature (storage) | 60 °C | |

| Max. back pressure (abs.) | 1.1 bar | |

| Inlet connection | Hose nozzle DN 6-10 mm | |

| Outlet connection | Hose nozzle DN 8-10 mm | |

| Coolant connection | 2 x hose nozzle DN 6-8 mm | |

| Rated motor power | 0.16 kW | |

| Protection class IEC 60529 | IP 20 | |

| Dimension L in mm | 300 mm | |

| Dimension B in mm | 306 mm | |

| Dimension H in mm | 400 mm | |

| Weight | 7.7 kg | |

| Noise (sound pressure level) in dBA at 50 Hz or 1500 rpm/62% (VARIO)/1500 rpm (VARIO-SP)/12500 Upm (VACUU·PURE®) | 42 dBA | |

| ATEX conformity | II 3/- G Ex h IIC T3 Gc X Internal Atm. only | |

| NRTL certification | Yes | |

| Items supplied | Pumping unit completely mounted, ready for use, with manual. | |

| Rated mains voltage range 1 | 200-230 V | |

| Rated mains voltage range 2 | 100-120 V | |

| Mains frequency 1 | 50-60 Hz | |

| Mains frequency 2 | 50-60 Hz |

für Zoom klicken

für Zoom klicken