ME 4C NTChemistry diaphragm pump

Overview

- outstanding chemical resistance

- high performance even at low vacuum levels

- whisper quiet

- low vibration

- long diaphragm life, maintenance-free drive system

Ultimate vacuum

70 mbar

Max. pumping speed 50 Hz

3.9 m3/h

Chemistry diaphragm pump in action

Chemistry-design diaphragm pumps are an excellent solution for continuous, oil-free pumping of corrosive gases and vapors. The one-stage construction provides the advantageous combination of high pumping speed and low ultimate vacuum down to 70 mbar. All major parts in contact with pumped media are made of chemically resistant fluoroplastics. Well-proven PTFE sandwich diaphragms increase reliability and extend operating life. The NT-series features further improved performance data, higher tolerance for condensates and simplified maintenance. The ME 4C NT is also available as chemistry vacuum system ME 4C NT +2AK with inlet separator to protect the pump against particles and liquid droplets, plus outlet separator to collect condensate.

für Zoom klicken

für Zoom klicken

Technical data and graphs

| Max. pumping speed 50 Hz | 3.9 m3/h | |

| Max. pumping speed 60 Hz | 2.6 cfm | |

| Ultimate vacuum | 70 mbar / 52 torr | |

| Number of heads | 2 | |

| Number of stages | 1 | |

| Lower ambient temperature (operation) | 10 °C | |

| Upper ambient temperature (operation) | 40 °C | |

| Lower ambient temperature (storage) | -10 °C | |

| Upper ambient temperature (storage) | 60 °C | |

| Max. back pressure (abs.) | 1.1 bar | |

| Inlet connection | Hose nozzle DN 8-10 mm | |

| Outlet connection | Hose nozzle DN 8-10 mm | |

| Rated motor power | 0.18 kW | |

| Rated motor speed at 50/60 Hz | 1500/1800 min-1 | |

| Protection class IEC 60529 | IP 40 | |

| Dimension L in mm | 254 mm | |

| Dimension B in mm | 243 mm | |

| Dimension H in mm | 198 mm | |

| Weight | 11.1 kg | |

| Noise (sound pressure level) in dBA at 50 Hz or 1500 rpm/62% (VARIO)/1500 rpm (VARIO-SP)/12500 Upm (VACUU·PURE®) | 45 dBA | |

| ATEX conformity | II 3/- G Ex h IIC T3 Gc X Internal Atm. only | |

| NRTL certification | Yes | |

| Items supplied | Pump completely mounted, ready for use, with manual. | |

| Rated mains voltage range 1 | 230 V | |

| Mains frequency 1 | 50-60 Hz |

für Zoom klicken

für Zoom klicken

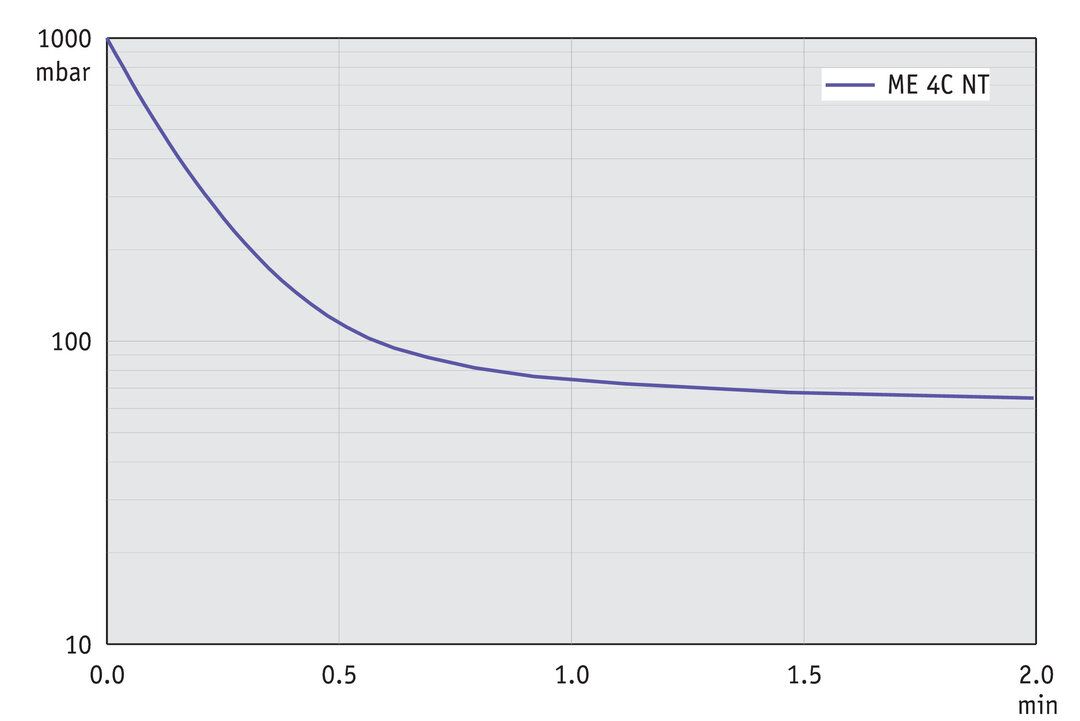

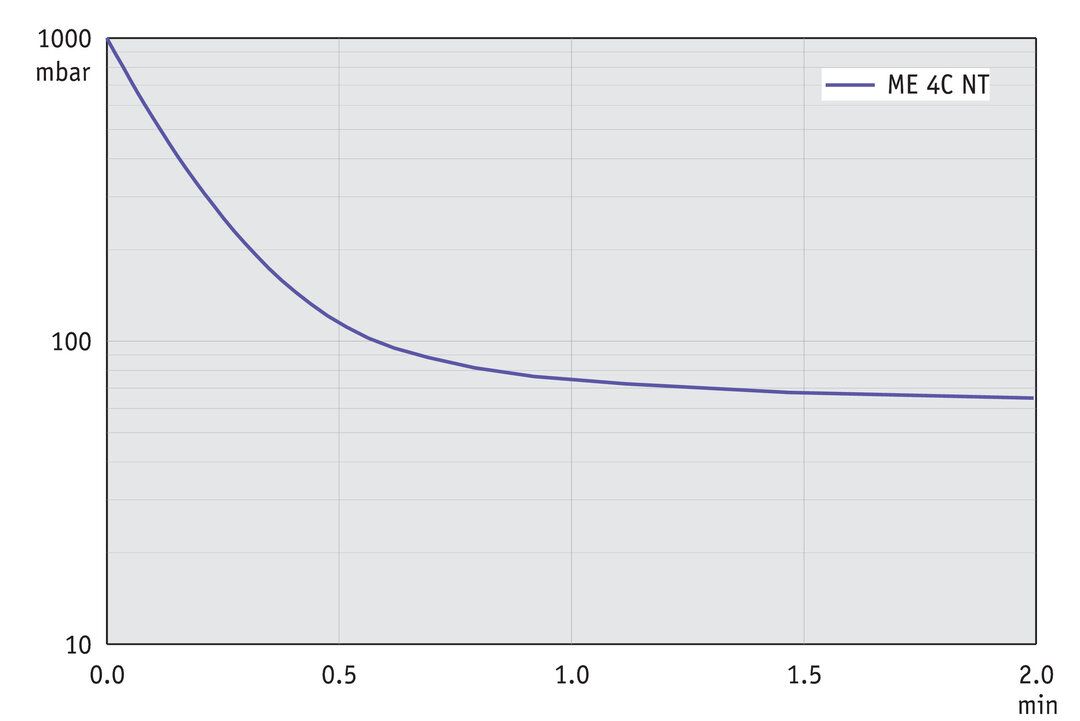

Pump down graph 50 Hz (10 l volume)

für Zoom klicken

für Zoom klicken

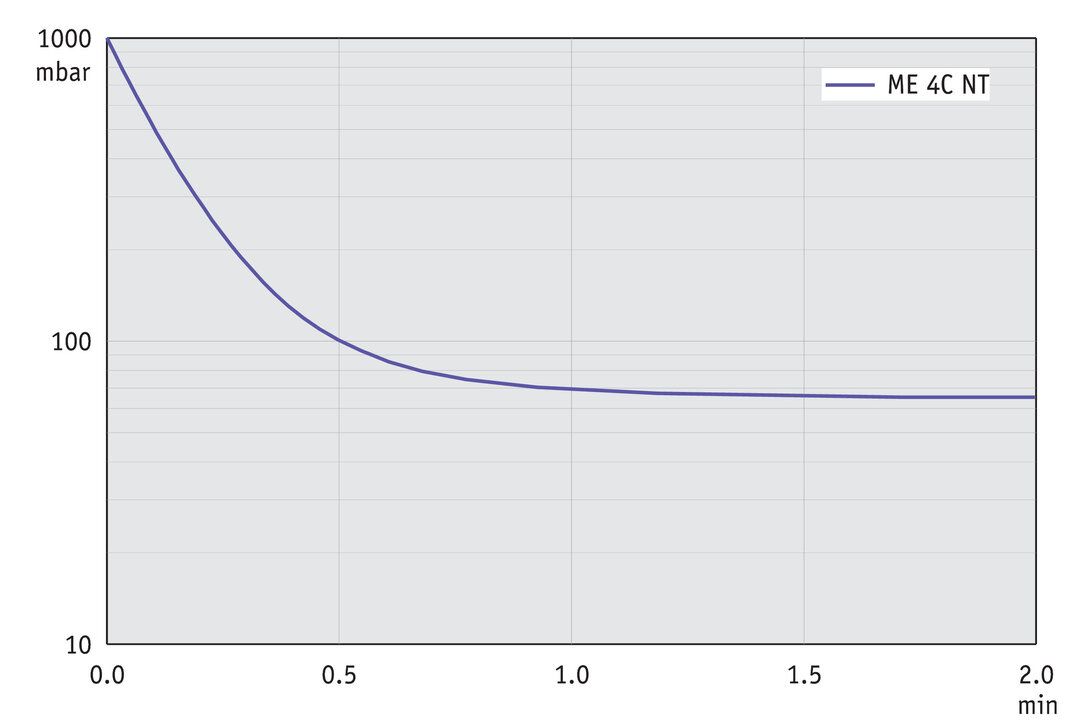

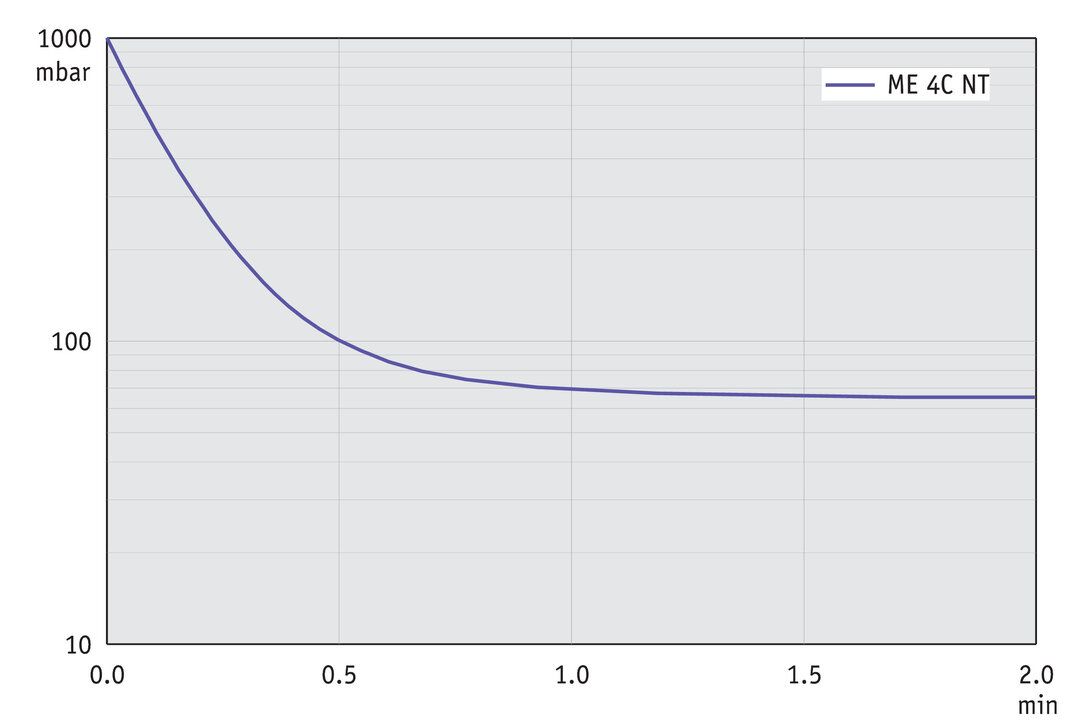

Pump down graph 60 Hz (10 l volume)

Downloads

Equipment

Related Products

Application examples

Chemistry diaphragm pump in action

Chemistry-design diaphragm pumps are an excellent solution for continuous, oil-free pumping of corrosive gases and vapors. The one-stage construction provides the advantageous combination of high pumping speed and low ultimate vacuum down to 70 mbar. All major parts in contact with pumped media are made of chemically resistant fluoroplastics. Well-proven PTFE sandwich diaphragms increase reliability and extend operating life. The NT-series features further improved performance data, higher tolerance for condensates and simplified maintenance. The ME 4C NT is also available as chemistry vacuum system ME 4C NT +2AK with inlet separator to protect the pump against particles and liquid droplets, plus outlet separator to collect condensate.

für Zoom klicken

für Zoom klicken

Technical data and graphs

| Max. pumping speed 50 Hz | 3.9 m3/h | |

| Max. pumping speed 60 Hz | 2.6 cfm | |

| Ultimate vacuum | 70 mbar / 52 torr | |

| Number of heads | 2 | |

| Number of stages | 1 | |

| Lower ambient temperature (operation) | 10 °C | |

| Upper ambient temperature (operation) | 40 °C | |

| Lower ambient temperature (storage) | -10 °C | |

| Upper ambient temperature (storage) | 60 °C | |

| Max. back pressure (abs.) | 1.1 bar | |

| Inlet connection | Hose nozzle DN 8-10 mm | |

| Outlet connection | Hose nozzle DN 8-10 mm | |

| Rated motor power | 0.18 kW | |

| Rated motor speed at 50/60 Hz | 1500/1800 min-1 | |

| Protection class IEC 60529 | IP 40 | |

| Dimension L in mm | 254 mm | |

| Dimension B in mm | 243 mm | |

| Dimension H in mm | 198 mm | |

| Weight | 11.1 kg | |

| Noise (sound pressure level) in dBA at 50 Hz or 1500 rpm/62% (VARIO)/1500 rpm (VARIO-SP)/12500 Upm (VACUU·PURE®) | 45 dBA | |

| ATEX conformity | II 3/- G Ex h IIC T3 Gc X Internal Atm. only | |

| NRTL certification | Yes | |

| Items supplied | Pump completely mounted, ready for use, with manual. | |

| Rated mains voltage range 1 | 230 V | |

| Mains frequency 1 | 50-60 Hz |

für Zoom klicken

für Zoom klicken

Pump down graph 50 Hz (10 l volume)

für Zoom klicken

für Zoom klicken