RZ 6Rotary vane pump

Overview

- high flow rates even at vacuum levels approaching ultimate vacuum

- high water vapor tolerance due to efficient gas ballast; very good ultimate vacuum even with gas ballast

- vacuum-tight at switch-off; external anti-suckback valve not needed

- large oil volume: Long intervals between oil changes

- ease of maintenance due to telescopic design

Ultimate vacuum

2 x 10-3 mbar

Ultimate vacuum with gas ballast

1 x 10-2 mbar

Max. pumping speed 50 Hz

5.7 m3/h

Rotary vane pump in action

These powerful rotary vane pumps feature a particularly compact design and low weight for pumps of this capacity. They are the ideal solution for a wide range of laboratory and process applications that require low ultimate vacuum at medium to increased gas flow rate. Various packages including pump, oil mist filter, etc. are available. Rotary vane pumps are used when an ultimate vacuum between a few mbar and down to 10-3 mbar has to be attained. Typical applications are degassing, lyophilization, fine vacuum distillation and drying chambers. The pumping unit PC 3 is the perfect choice for applications requiring special protection of pump and environment. Designed for the use in chemical laboratories the cold trap helps the pumps to handle large volumes of condensable vapors. The cold trap is metalized for extended coolant life and protected against implosion.

für Zoom klicken

für Zoom klicken

Technical data and graphs

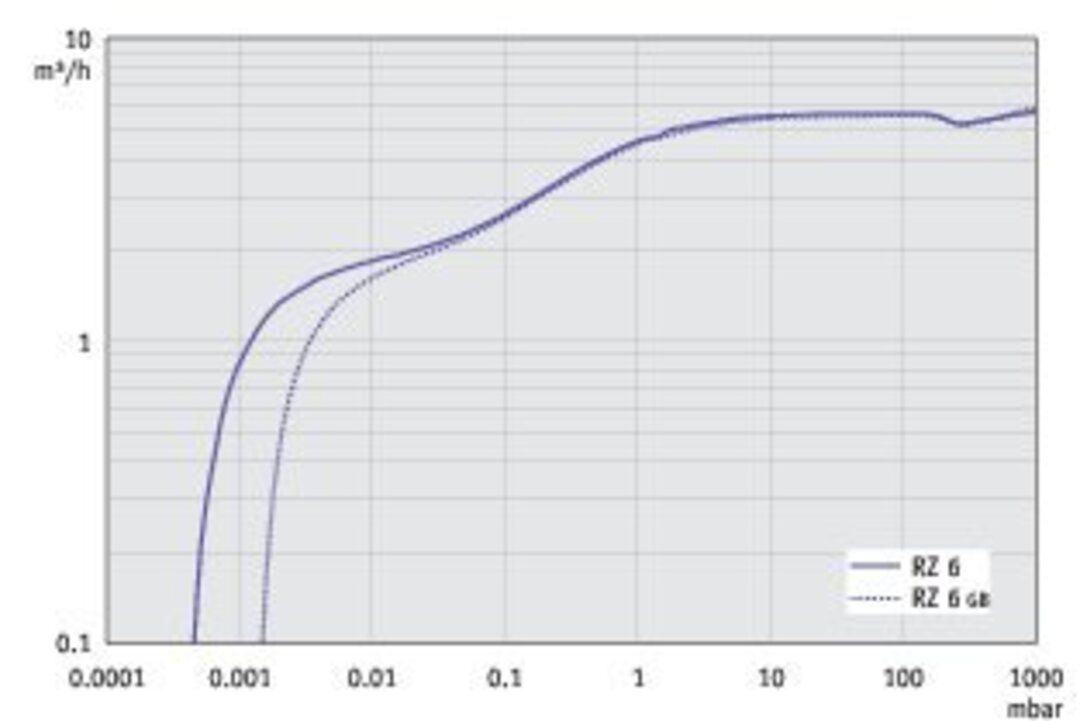

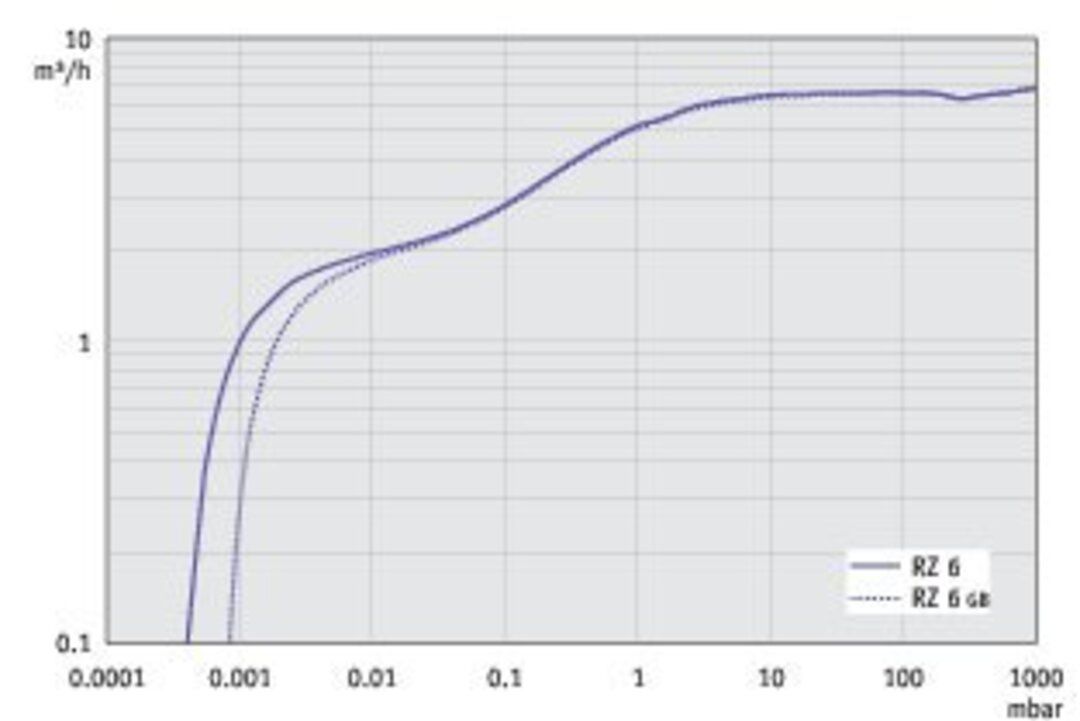

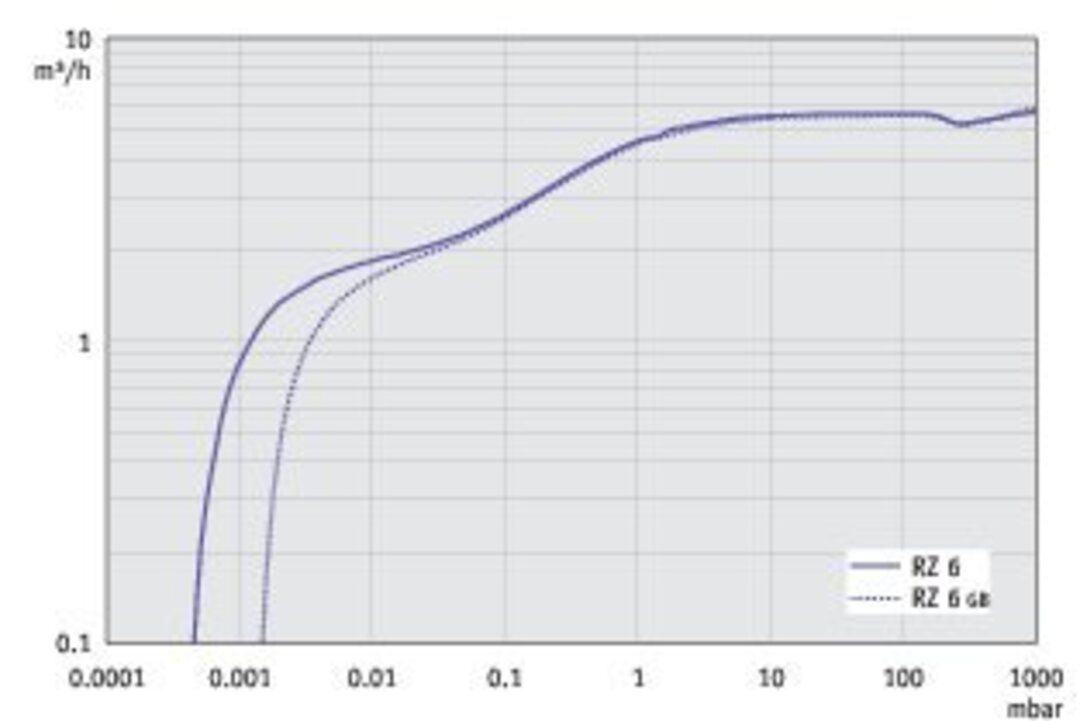

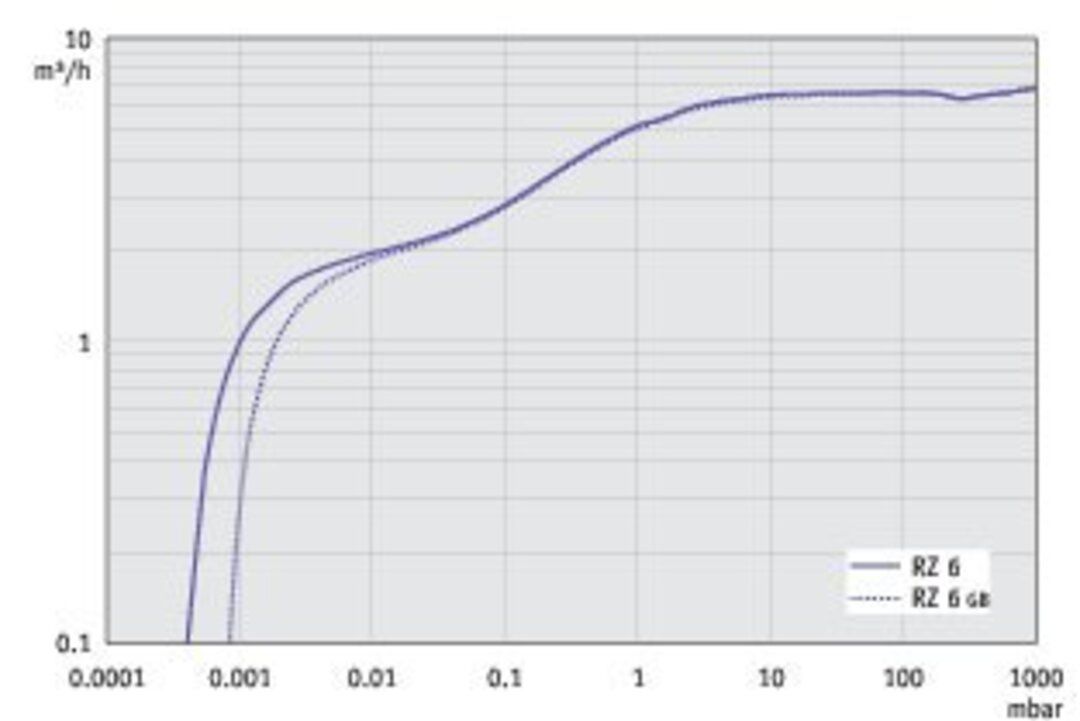

| Max. pumping speed 50 Hz | 5.7 m3/h | Select diagram |

| Max. pumping speed 60 Hz | 4.0 cfm | Select diagram |

| Ultimate partial vacuum (abs.) without gas ballast | 4 x 10-4 mbar | |

| Ultimate vacuum | 2 x 10-3 mbar / 1.5 x 10-3 torr | |

| Ultimate vacuum with gas ballast | 1 x 10-2 mbar / 0.75 x 10-2 torr | |

| Number of stages | 2 | |

| Vacuum controller | 17 | |

| Water vapor tolerance with gas ballast | 40 mbar | |

| Lower ambient temperature (operation) | 12 °C | |

| Upper ambient temperature (operation) | 40 °C | |

| Lower ambient temperature (storage) | -10 °C | |

| Upper ambient temperature (storage) | 60 °C | |

| Max. outlet pressure (abs.) | 1.1 bar | |

| Oil capacity (B-Oil) min. | 0.34 l | |

| Oil capacity (B-Oil) max. | 0.65 l | |

| Inlet connection | small flange KF DN 16 | |

| Outlet connection | Hose nozzle DN 8-10 mm | |

| Rated motor power | 0.3 kW | |

| Rated motor speed at 50/60 Hz | 1500/1800 min-1 | |

| Protection class IEC 60529 | IP 40 | |

| Dimension L in mm | 370 mm | |

| Dimension B in mm | 142 mm | |

| Dimension H in mm | 207 mm | |

| Weight | 16.4 kg | |

| Noise (sound pressure level) in dBA at 50 Hz or 1500 rpm/62% (VARIO)/1500 rpm (VARIO-SP)/12500 Upm (VACUU·PURE®) | 50 dBA | |

| NRTL certification | No | |

| Items supplied | Pump oil filled and completely mounted, ready for use, with manual. | |

| Rated mains voltage range 1 | 230 V | |

| Mains frequency 1 | 50-60 Hz |

für Zoom klicken

für Zoom klicken

Max. pumping speed 50 Hz

für Zoom klicken

für Zoom klicken

Max. pumping speed 60 Hz

für Zoom klicken

für Zoom klicken

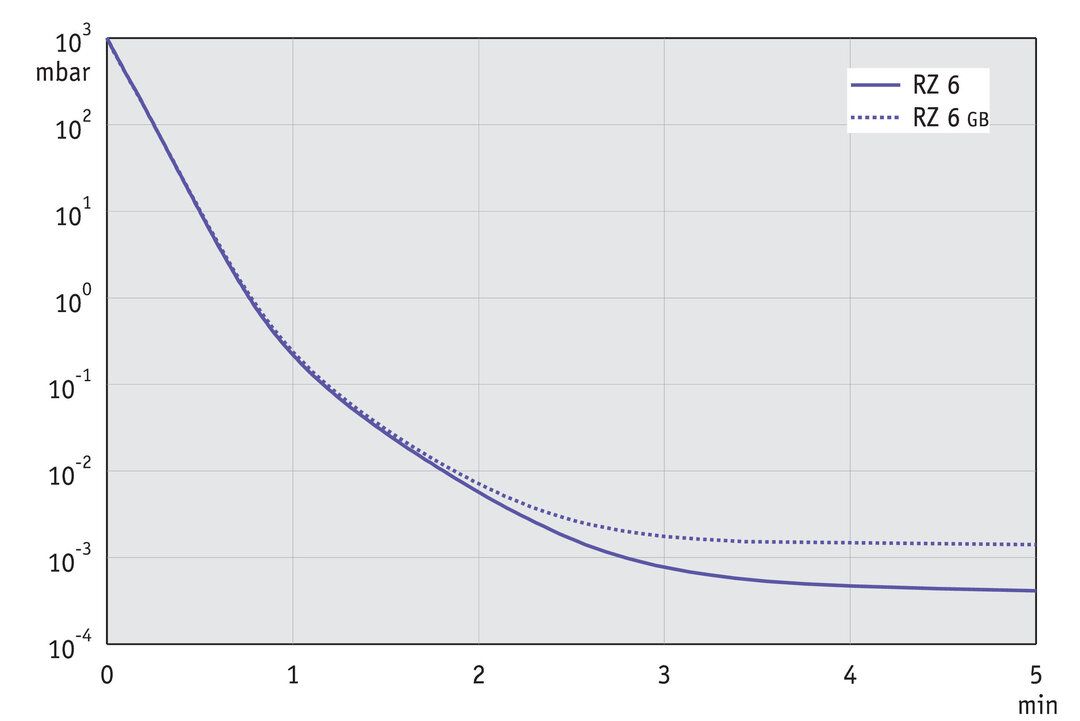

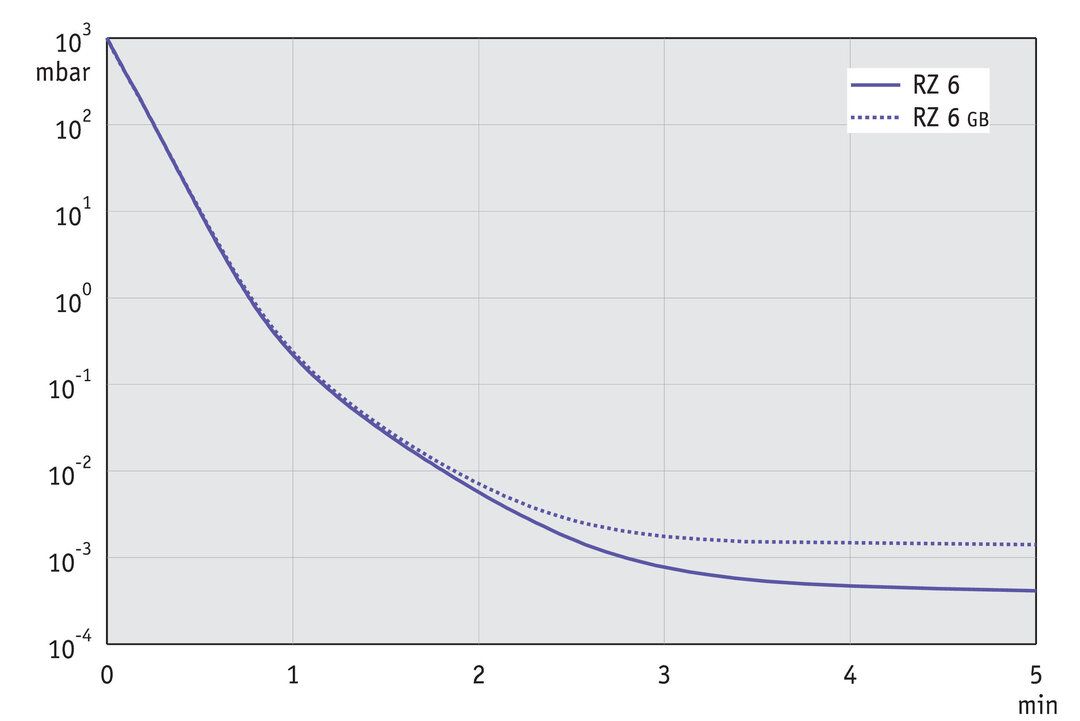

Pump down graph 50 Hz (10 l volume)

für Zoom klicken

für Zoom klicken

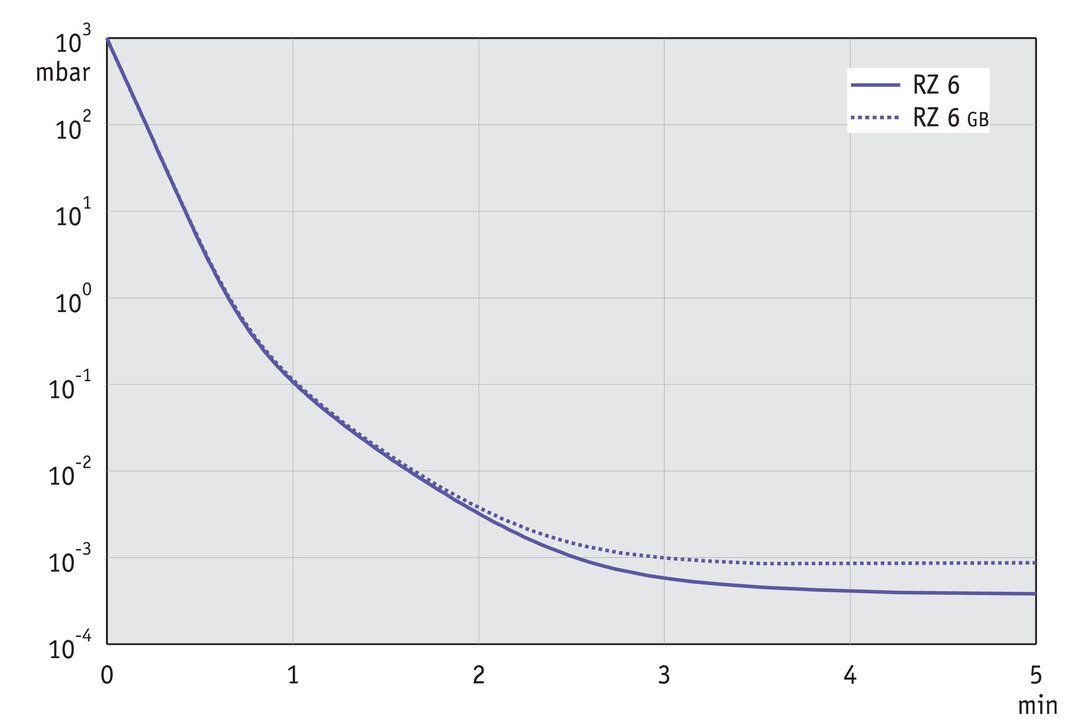

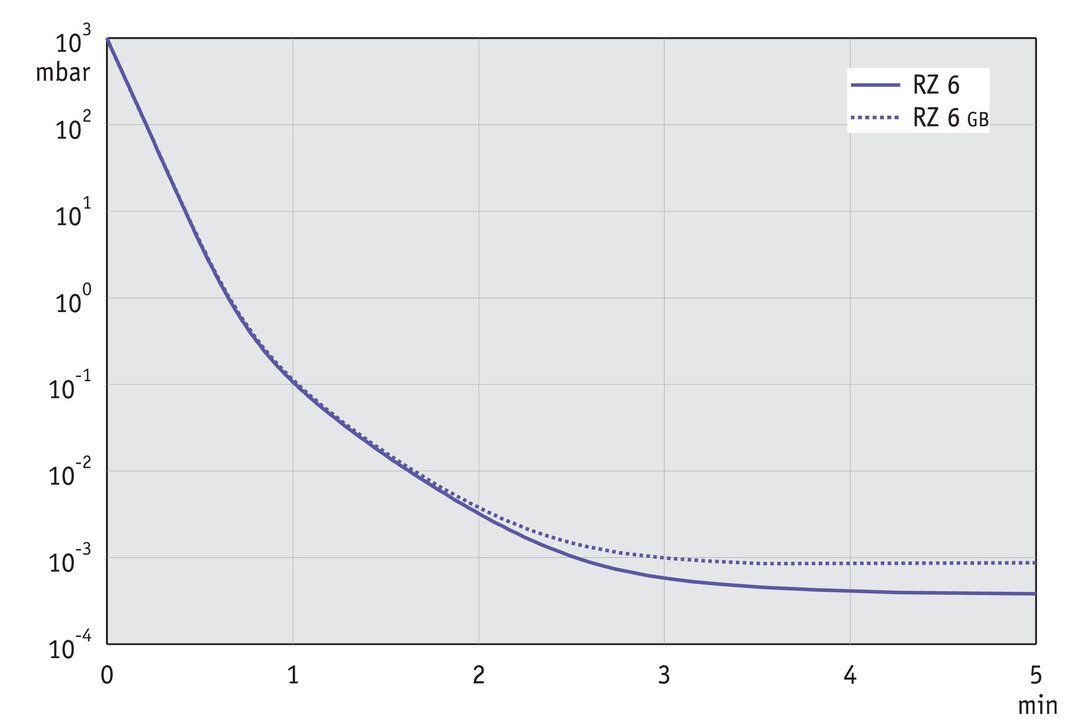

Pump down graph 60 Hz (10 l volume)

Downloads

Equipment

Related Products

Application examples

Rotary vane pump in action

These powerful rotary vane pumps feature a particularly compact design and low weight for pumps of this capacity. They are the ideal solution for a wide range of laboratory and process applications that require low ultimate vacuum at medium to increased gas flow rate. Various packages including pump, oil mist filter, etc. are available. Rotary vane pumps are used when an ultimate vacuum between a few mbar and down to 10-3 mbar has to be attained. Typical applications are degassing, lyophilization, fine vacuum distillation and drying chambers. The pumping unit PC 3 is the perfect choice for applications requiring special protection of pump and environment. Designed for the use in chemical laboratories the cold trap helps the pumps to handle large volumes of condensable vapors. The cold trap is metalized for extended coolant life and protected against implosion.

für Zoom klicken

für Zoom klicken

Technical data and graphs

| Max. pumping speed 50 Hz | 5.7 m3/h | Select diagram |

| Max. pumping speed 60 Hz | 4.0 cfm | Select diagram |

| Ultimate partial vacuum (abs.) without gas ballast | 4 x 10-4 mbar | |

| Ultimate vacuum | 2 x 10-3 mbar / 1.5 x 10-3 torr | |

| Ultimate vacuum with gas ballast | 1 x 10-2 mbar / 0.75 x 10-2 torr | |

| Number of stages | 2 | |

| Vacuum controller | 17 | |

| Water vapor tolerance with gas ballast | 40 mbar | |

| Lower ambient temperature (operation) | 12 °C | |

| Upper ambient temperature (operation) | 40 °C | |

| Lower ambient temperature (storage) | -10 °C | |

| Upper ambient temperature (storage) | 60 °C | |

| Max. outlet pressure (abs.) | 1.1 bar | |

| Oil capacity (B-Oil) min. | 0.34 l | |

| Oil capacity (B-Oil) max. | 0.65 l | |

| Inlet connection | small flange KF DN 16 | |

| Outlet connection | Hose nozzle DN 8-10 mm | |

| Rated motor power | 0.3 kW | |

| Rated motor speed at 50/60 Hz | 1500/1800 min-1 | |

| Protection class IEC 60529 | IP 40 | |

| Dimension L in mm | 370 mm | |

| Dimension B in mm | 142 mm | |

| Dimension H in mm | 207 mm | |

| Weight | 16.4 kg | |

| Noise (sound pressure level) in dBA at 50 Hz or 1500 rpm/62% (VARIO)/1500 rpm (VARIO-SP)/12500 Upm (VACUU·PURE®) | 50 dBA | |

| NRTL certification | No | |

| Items supplied | Pump oil filled and completely mounted, ready for use, with manual. | |

| Rated mains voltage range 1 | 230 V | |

| Mains frequency 1 | 50-60 Hz |

für Zoom klicken

für Zoom klicken

Max. pumping speed 50 Hz

für Zoom klicken

für Zoom klicken

Max. pumping speed 60 Hz

für Zoom klicken

für Zoom klicken

Pump down graph 50 Hz (10 l volume)

für Zoom klicken

für Zoom klicken